wire bending test|cold bending wire testing : broker Instron’s 3-point and 4-point flexure fixtures are recommended to perform bend testing of cables and wires. Bluehill ® Universal software is implemented to set-up quick and easy methods to run bend tests at certain end-of-test conditions. WEBShinobu Kocho [kimetsu no yaiba] (mandymoonof) 196 upvotes · 3 comments. 319K subscribers in the DemonSlayer34 community. Welcome to r/DemonSlayer34, THE .

{plog:ftitle_list}

WEB1. 2. 3. 4. 5. 6. 7. 8. 9. Next. Coroa rabuda da academia. 20.5k 82% 24sec - 1080p. Fodendo a rabuda. 765 1min 16sec - 1080p. Putariasdocasal20. putariasdocasal20. 2.7k 6min - 720p. BBW branquinha fudendo de 4. 4k 84% 2min - 360p. Pegando a coroa branquinha e bunduda. 20.4k 92% 1min 12sec - 480p. novinha fodendo lindissima. 21.8k .

ASTM E290-22. Standard Test Methods for Bend Testing of Material for Ductility. Significance and Use. 5.1 Bend tests for ductility provide a simple way to evaluate the quality of materials .

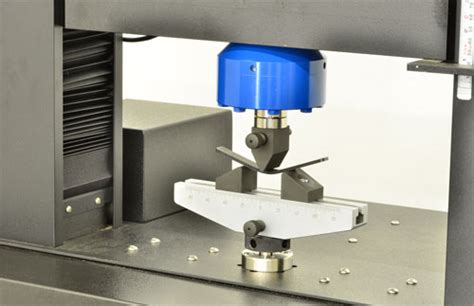

The bending test provided data on the force or load required to bend the wire over the range of motion of the test actuator. As the actuator pressed into the cable, the bending radius of the.With the help of bend tests (flexural strength tests), one can determine the maximum bending stress a cable or wire can handle an indefinite number of times without breaking. Our bend . Dynamic Bend Testing is a critical method used to evaluate the pliability and endurance of cables and wires under repetitive flexing conditions. By consistently bending .

Instron’s 3-point and 4-point flexure fixtures are recommended to perform bend testing of cables and wires. Bluehill ® Universal software is implemented to set-up quick and easy methods to run bend tests at certain end-of-test conditions.

Cable Cold Bend Testing. The Cold Bend Test is conducted according to IEC 60811-504 and is designed to assess the performance of electrical cables at low temperatures. The test must be carried out on samples of insulation and .Objective. This document describes the specification and instruction for assessing the quality and usability of cords and cable assemblies for power supplies. Scope. The scope of this .How tightly can the copper or aluminum wire safely bend in an installation? What guidelines do we need to follow, and how can we prevent damage in the first place? Although every wire is different, there are general guidelines to help .

Explore the comprehensive range of tests conducted on electrical cables, from the persulphate test to high voltage and insulation resistance tests. Discover the procedures and . Also, the FE simulation of the bending of wire round a mandrel reported in the literature was conducted by pinning the nodes on one end of the wire to the mandrel and applying a concentrated load .

The “flex life test” (or alternate bending test) is based on the standard specification ASTM B470. During the test, cables or wires under test are alternately bent over defined radii in cycles. The defined bending angle, .

Wire Construction: Jacketed SHIELDED cable/ 6,500 I AWG#24 stranded 5 (SA) 6,000 I Connector: _____ Overmold Material: JBXFDBO4MCSOSMR Henkel OM 638 Note: SA = soaked . The bending test shall cover both cord and strain relief. The test is over when the first conductor is broken, the resistance of the conductor increases more than 20% or .Full Automatic cnc Wire Bending Machine Price / Used cnc 3d Wire Bending Machines / Wire Bending Test Machine ,222.00 - ,888.00. Min. Order: 1 set. 5 yrs CN Supplier. Bend Test Machine Price. Bend test can be performed either on a special bend testing machine or using the jigs on Universal Testing Machine as shown in the picture shown above. So, the cost can be USD 3000 to USD 30000 for the machine. Bend Test mandrel diameter. The selection of the bend test mandrel diameter is as per the applicable code or .Application of UL 87 Wire Bending Test Machine. Test plug lead wire and the bending strength of the wire, can be automatically counted at the same time show the conductor resistance of the wire, the test material bending broken line, and can automatically stop operation. Characteristics of UL 87 Wire Bending Test Machine

Our Solution. Instron’s 3-point and 4-point flexure fixtures are recommended to perform bend testing of cables and wires. Bluehill ® Universal software is implemented to set-up quick and easy methods to run bend tests at certain end-of-test conditions. Furthermore, Instron custom fixtures are designed for specific applications, such as cutting of cables and wires, to .

standard bend testing methods

The test methodology requires a low temperature chamber capable of maintaining the specified test temperature and bending apparatus as described in IEC 60811-504. The sample should be of sufficient length to achieve the specified number of rotations around a mandrel that has a nominal diameter of between 4 and 5 times that of the test sample .

An overview of the types of pliers and variety of wires used in making orthodontic appliances by the basic methods for bending curves, loops, and right angle.The test and apparatus used is designed to comply with the following standards; IEC 60227-2 clause 5.6.3.2 , IEC 60227-2 clause 3.2 and IEC 60335-1 clause 25.14. The cord bend test sees a sample of cord of appropriate length fixed in the apparatus and then loaded with a weight having a mass of 0.5kg.Traditional Dental Aptitude Test and academic grade point average have been shown to be poor predictors of clinical performance by dental students. To refine predictors of psychomotor skills, a wire-bending test was given to 105 freshmen at the .

Fig.1(a) shows a guided bend test jig that uses a male and a female former, the commonest form of equipment Fig.1(b) shows a wrap-around guided bend test machine that works on the same principles as a plumber's pipe bender. The strain applied to the specimen depends on the diameter of the former around which the coupon is bent and this is related to the thickness of .

The specimen used for the three-point bending test is a beam similar to the one sketched in Figure 3. . the wire of the crack-mouth opening displacement gauge; #4: The switch for setting the power mode of the machine; #5: The fixtures of the machine. 2.1 Specimen preparationVerreet et al.: A new and innovative wire rope bending fatigue machine 9 In the bending fatigue machines of the new design a rope is reeved from a drum (Fig. 6 left and Fig. 7) through a sheave system with e.g. 5 sheaves (Fig. 6 right and Fig. 8) and back to the drum. Fig. 9: Distribution of bending cycles along the length of the test rope.Reach inside panels, disconnects, and raceway to bend and position heavy duty cable with greater precision and less fatigue than bending by hand. The dies on the ends of these benders are sized to handle large wire gauges; fit your cable into the dies and push or pull the handle to bend.. Keep style A benders in your belt pouch for on-the-fly bends and especially tight spots. Although rotary bend wire fatigue is a relatively common test, the speed used to perform testing can vary greatly. Given that in vivo loading occurs at a much slower rate than the maximum speed of motors used in wire fatigue testers (e.g., approximately 72 beats per minute for cardiac loading versus 25,000 or more revolutions per minute (RPM) for a high-speed .

Wire bending test machines are an important piece of testing equipment used to evaluate the bending properties of different types of wires. The machine used for plug leads, power cord, USB cable, headphone cable, .JB/T 11868.2-2014, Copper-clad steel wire for electrical purposes — Part2: Annealed copper-clad steel wires (in Chinese) [3] EN 10264-3:2012, Steel wire and wire products — Steel wire for ropes — part 3 Round and shaped non alloyed steel wires for high duty application. [4] GB/T 352-2002, Locked coil wire rope (in Chinese) FREE-BEND TEST FOR WELD TESTING. Free Bend Test measures the ductility of the weld metal in a butt joint in a plate or pipe in terms of elongation percentage. The thickness of the specimen is the same as that of the plate or the pipe, the width is 1.5times the thickness and .

I thought I'd upload a video about a wire bending jig / wire former I made to possibly help someone else out who may have a need to make something similar. A. The flexibility of a wire/cable is dependent on a combination of the conductor and insulation constructions. Conductors with more strands are often better ab.The test procedure for performing the cold wire-bending test is outlined below. 1. A wire sample approximately 20 cm in length is initially tested at room temperature. The wire is placed across the supports at the base of the bending press. The bending press is activated, pushing the center of the wire down approximately 3 cm.Bend Testing is a stress test which subjects the unit under test (typically printed wiring boards and handheld electronic products) to monotonic flexural loading. Monotonic bend testing is conventionally used to characterize fracture strength of interconnects between board and components or the interconnection structure within the board. A .

Small-scale bending tests (Fig. 7) provide a simply fixable set-up for anchors characterization in combined shear-bending and even in equilibrium critical application.It is probably the closest combination of stresses to simulate a real-scale bended structure, which is possible through a small-scale test [97].In this case, recovery of characterization data from the .Introducing our newest tool on the bench 👉 the wire bending jig (code CG13712). Perfect for making repeatable shapes in wire: triangle, d-shape and s-style .The test of wire by reverse bending to rupture is specific in that only a very small part of the sample is undergoes plastic deformation. Thanks to this, the test result (i.e. the number of bends to rupture) strongly depends on the wire area affected by bending. If, in fact this area contains an inclusion or surface cracks, the test result will .bility by nearly all the ropes in operation. However, the statistical spread of the test results during bending fatigue tests indicates that it is virtually impossible to predict a number of bending cycles which will be achieved in any case. Therefore a number of bending cycles N10 is calculated which is achieved by 90 % of all the wire ropes .

cold bending wire testing

Sexy babe Kim B swallowed big dick and enjoyed hardcore pussy fucking. 856 10min - 1080p. Kim is an amateur Ebony slut with big natural tits and a bubble butt. Watch as she wraps her thick, dick-sucking lips around big white cock, while raring to get fucked and cum hard in interracial fake casting. For full HD scene, visit AFRICANCASTING!

wire bending test|cold bending wire testing